Construction of Anglo Global Share Services’ Ikusasa building on track

Advertising

30-09-2021

Read : 722 times

Property Wheel

Source

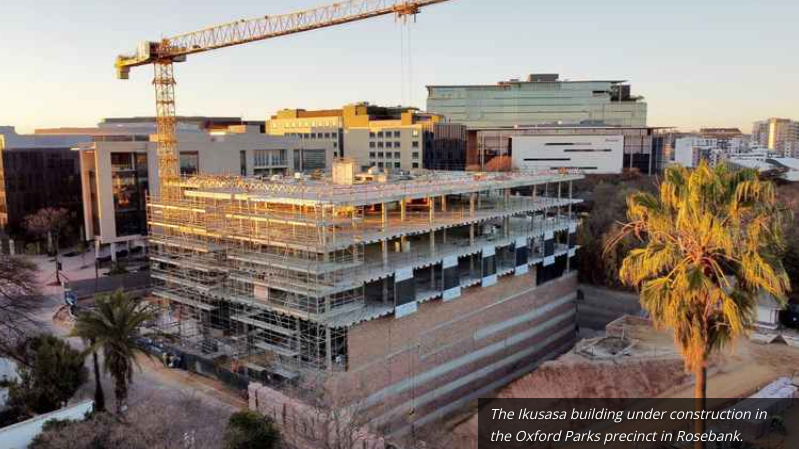

Concor is leveraging its depth of skills with Anglo American Global Shared Services’ (GSS) Ikusasa building in the Oxford Parks precinct in Rosebank, Johannesburg.

Warren Mills, Concor site agent responsible to the project, says that fast-track construction has become increasingly prevalent as it allows occupancy within a shorter period.

“It does, however, require a more agile approach to construction, especially as this type of project is far more complex with numerous subcontractors interfacing on a tight construction programme” he says.

“On the Ikusasa project, we will eventually have more than 70 subcontractors on site, and this is in addition to our own team of core disciplines. So, it is all about tight control over scheduling and close co-ordination with all”.

Mills says that bulk excavations for the three basement levels began in January 2021 and the concrete structure for the four-storey building topped out in August 2021.

Given the construction schedule, the decision was made to increase the size of the foundation piles allowing the columns to be cast over the piles. He explains that traditionally, one would excavate around the pile and cast a concrete base or pile cap on top of the pile. However, by increasing the size of the pile, the need for concrete bases was eliminated, resulting in a time saving to the project. In total, 115 piles were cast.

Once the piling subcontractor casted the piles, Concor inserted the column starter bars into the concrete where after the normal shuttering process was followed, and the concrete columns cast. Columns were spaced on an 8.4 metre by 8.4 metre grid with the decking installed for the suspended concrete slap pour.

The basement level pours were split into five separate pours to accommodate the construction schedule and allow other ongoing work to continue. There are three full basement levels with a fourth smaller ramp connection to a future phase.

Space constraints as well as financial feasibility informed the decision to go with a ready-mix service provider, and this decision formed part of the overall risk management on the project.

“The concrete design mixes for various aspects of the build, including all slabs, considered the need for a low carbon footprint with a low Portland cement being used, seeing this fall into the green concrete category” says Mills.

“However, in the case of the column mix, this was superseded by the need for an early high strength concrete that would facilitate the ongoing fast track construction progress”.

Construction of the top structure continued with the building of a double volume space between the ground and the first floors and the three office levels above. The fourth slab was poured in mid-August 2021 to close off the third office floor.

“Traditionally when constructing an office building, we would require three levels of back prop and support work, however on this project we managed to engineer a solution that required only two levels of back propping. Adopting this innovative construction methodology facilitated an earlier access state for subcontractors to start façade installations, wet work services and follow-on trades,” Mills says.

Close collaboration between Concor and the client from the start of the project made it possible to accelerate long lead trades facilitating a more integrated approach with significant savings in time enabling the fast-track programme to stay on track.

A significant advantage is that the same engineering firm has been used for both the structure and the façade for the curtain wall. This allowed the design and manufacturing of the elements for the façade to begin while the contractor was still busy constructing the concrete structure. Accurate dimensioning of the façade was possible using sophisticated software that allowed modelling of the full façade around the concrete structure. In adopting these approaches, Concor unlocked two long lead materials, being the glass and façade tiling.

The façade itself is a unitized system which is less labour intensive to install and does not require a full façade scaffold for installation. Both these will also contribute to cost and time savings on the project.

Mills explains that Concor’s scope of work on the Ikusasa project includes the fit-out of the entire building, and this will see the company co-ordinate the installation of all fittings and fixtures before handover of the building to AGSS at the end of January 2022.

Recent News

Here are recent news articles from the Building and Construction Industry.

Have you signed up for your free copy yet?